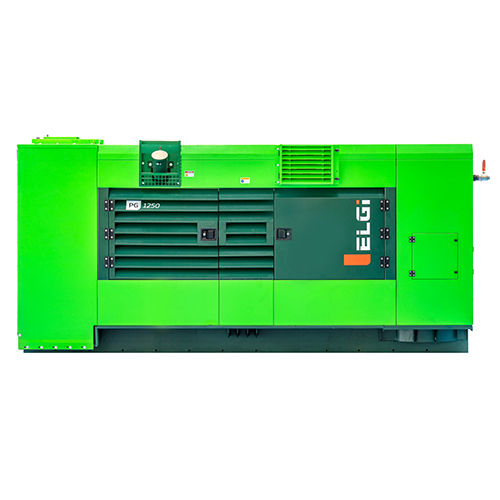

ELGi Water Well Air Compressor

Product Details:

- Control System DOL Starter

- Drive Type Belt Driven

- Power Rating 15 kW

- Weight 950 Kg

- Frequency 50 Hz

- Flow Rate 100 CFM

- Filtration Grade Industrial Grade

- Click to View more

X

ELGi Water Well Air Compressor Product Specifications

- Industrial Grade

- DOL Starter

- 85 dB(A)

- Belt Driven

- Water Well Drilling

- Oil Lubricated

- Reciprocating Compressor

- Electric Motor

- Electric

- 415 V

- Stationary

- Air Cooled

- 100 CFM

- No

- 20 HP

- 50 Hz

- 500 Litres

- Three Phase

- 12 Bar

- 15 kW

- 950 Kg

- Two Stage

- Cast Iron

- 50°C

- 1.5 Inch

- Base Mounted

- Water Well Drilling, Borewell Drilling

- Blue

Product Description

SKID MOUNTED COMPRESSORS 185-1500 CFM

ELGi's range of portable skid diesel air compressors are ideal for mounting on drill rigs or utility trucks and best suited for water well drilling. ELGi is one of the very few companies in the world to offer the full range of single and two stage compressors in this range. ELGi portable compressors are widely used by drill rig OEMs globally for efficiency, size and maneuverability

Efficient Performance for Drilling Applications

This compressor is tailored for intense drilling tasks, supporting both water well and borewell operations. Its robust motor and efficient dual-stage design ensure uninterrupted air flow, even in challenging environments, making it ideal for deep drilling projects.

Sturdy Construction for Extended Durability

Built from cast iron and featuring a heavy-duty stationary setup, the ELGi compressor boasts notable longevity and resistance to wear. Its oil-lubricated system ensures smooth operation, while industrial-grade filtration protects internal components and maintains air quality.

Safe and User-Friendly Operation

Operating on a three-phase, 415V electric power supply, this device is equipped with a DOL starter for safe motor control. The air-cooled design manages heat efficiently, and its 1.5-inch outlet provides secure connections for drilling equipment.

FAQ's of ELGi Water Well Air Compressor:

Q: How does the ELGi Water Well Air Compressor facilitate water well and borewell drilling?

A: This compressor provides the high-pressure, consistent air supply vital for efficient drilling operations. Its two-stage mechanism ensures optimal airflow and pressure, supporting the removal of debris and aiding in well formation.Q: What benefits does cast iron construction offer for this compressor?

A: Cast iron enhances the durability and resilience of the compressor, making it capable of withstanding heavy usage and harsh drilling environments. This material extends the operational life and provides reliability during intensive drilling activities.Q: When should the compressor's air tank be checked or serviced?

A: For optimal performance and safety, it is recommended to check the 500-liter air tank regularly for wear, leaks, and proper pressure levels before each drilling session and follow the manufacturer's maintenance schedule.Q: Where can this compressor be installed for maximum efficiency?

A: It should be installed in a stationary position on a level, solid base near the drilling site, ensuring proper ventilation due to its air-cooled design and access to a three-phase, 415V power source.Q: What is the process for starting and operating the compressor?

A: Start by confirming all connections and safety checks. Use the DOL starter to power up the electric motor. Monitor pressure levels and noise during operation, adhering to prescribed safety measures, and ensure proper lubrication and cooling.Q: How does the oil lubrication system improve compressor performance?

A: The oil-lubricated mechanism reduces friction and wear within moving parts, ensuring smoother performance and decreasing the risk of overheating, which is particularly beneficial for continuous or heavy-duty drilling tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese